Supermaker SLA400

Designed for demanding manufacturing environments, the SLA400 combines an expanded build volume with industrial-grade reliability to support large-scale stereolithography applications. It achieves exceptional accuracy and smooth surface finishes across full-bed productions, making it ideal for manufacturing big-sized functional prototypes, automotive components, architectural models, and medical devices. With enhanced stability and precision at scale, this system meets the needs of service bureaus, automotive OEMs, and medical labs seeking uninterrupted, high-yield 3D printing.

Accelerated Production

High-velocity scanning up to 10,000mm/s maintains precision at maximum throughput. Perfect for rapid iteration cycles and production-scale manufacturing demands.

Broad Material Compatibility

Supports 355-380nm wavelength-specific resins for diverse printing applications. Enables production of castable, engineering, and specialty models with precise curing performance.

Swift Material Swap

Quick-change resin tank system facilitates rapid material transitions and cleanup. Optimizes workflow efficiency for multi-material production environments.

Mobile Oversight

Live print monitoring through mobile connectivity allows real-time oversight from any location. Ensures production continuity and instant status updates for unmanned operations.

Environment Stability

Active climate management maintains ideal temperature and humidity levels throughout printing. Guarantees layer adhesion integrity and dimensional accuracy across all geometries.

System Safeguard

Intelligent power management detects and prevents electrical anomalies automatically. Shields critical components from damage during long-duration industrial printing tasks.

Unified Control

Seamless hardware-software synergy through industrial computing architecture. Enables flawless operation and reduced latency for complex printing requirements.

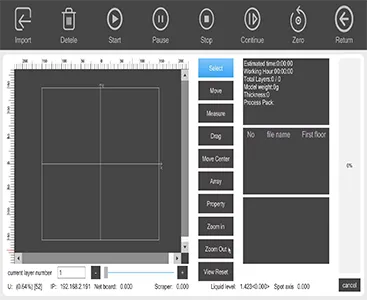

Customizable Software

Self-developed software allows full customization of printing parameters and functions. Enables tailored workflows for specific materials and advanced printing techniques.