Supermaker SLA1200

Setting new standards in large-format additive manufacturing, the SLA1200 delivers the industry’s largest stereolithography build volume with twin-laser precision for mega-scale industrial production. Engineered for fabricating ultra-large architectural components, full-scale transportation prototypes, aerospace structural parts, and industrial molds with uncompromised detail and stability. Its synchronized dual-laser system and thermally stabilized frame ensure high-speed, production-grade accuracy for the most demanding manufacturing applications across aerospace, automotive, and heavy equipment industries.

Accelerated Printing

Dual-laser technology enables simultaneous curing, dramatically reducing build time while maintaining high resolution. Ideal for time-sensitive projects and high-volume production requirements.

Giant Models

Industry-leading build volume enables production of exceptionally large-scale models with uncompromised precision. Ideal for architectural monuments, full-scale automotive prototypes, and oversized industrial components.

Swift Vat Change

Modular resin tank design allows effortless swapping between materials, streamlining workflow transitions and minimizing operational interruptions for multi-material applications.

Mobile Oversight

Live print monitoring through mobile connectivity allows real-time oversight from any location. Ensures production continuity and instant status updates for unmanned operations.

Environment Stability

Active climate management maintains ideal temperature and humidity levels throughout printing. Guarantees layer adhesion integrity and dimensional accuracy across all geometries.

System Safeguard

Intelligent power management detects and prevents electrical anomalies automatically. Shields critical components from damage during long-duration industrial printing tasks.

Unified Control

Seamless hardware-software synergy through industrial computing architecture. Enables flawless operation and reduced latency for complex printing requirements.

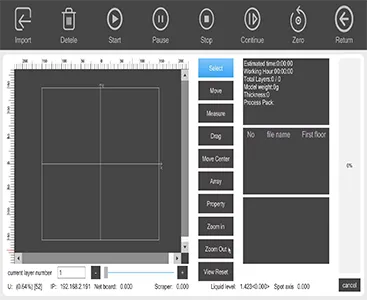

Customizable Software

Self-developed software allows full customization of printing parameters and functions. Enables tailored workflows for specific materials and advanced printing techniques.