Supermaker SLA800

Representing the pinnacle of large-format resin printing, the SLA800 delivers an exceptionally massive build volume for the most demanding industrial applications. Engineered for mega-scale production, it effortlessly manufactures oversized architectural components, full-scale automotive prototypes, aerospace tooling, and medical equipment housings with exceptional dimensional accuracy. The machine’s ultra-stable platform and advanced motion system ensure flawless performance under continuous heavy-duty operation, serving industries where size, speed, and reliability are critical.

Batch Production

Enables simultaneous printing of multiple large models in single build cycles. Maximizes productivity for industrial-scale manufacturing and high-volume part production.

Industrial Parts

Specifically engineered for large industrial component manufacturing. Delivers precision and durability for functional prototypes, tooling, and end-use production parts.

Easy Vat Swap

Quick-release resin vat system enables fast material changes and maintenance. Reduces downtime and supports flexible multi-material workflows for varied applications.

Mobile Oversight

Live print monitoring through mobile connectivity allows real-time oversight from any location. Ensures production continuity and instant status updates for unmanned operations.

Environment Stability

Active climate management maintains ideal temperature and humidity levels throughout printing. Guarantees layer adhesion integrity and dimensional accuracy across all geometries.

System Safeguard

Intelligent power management detects and prevents electrical anomalies automatically. Shields critical components from damage during long-duration industrial printing tasks.

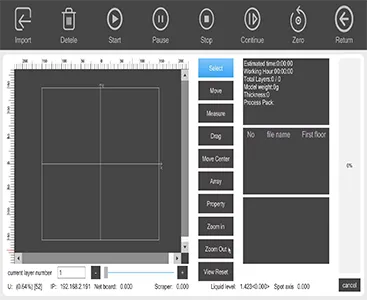

Unified Control

Seamless hardware-software synergy through industrial computing architecture. Enables flawless operation and reduced latency for complex printing requirements.

Customizable Software

Self-developed software allows full customization of printing parameters and functions. Enables tailored workflows for specific materials and advanced printing techniques.