Supermaker SLS3540Pro

Designed for large-scale manufacturing facilities, the SLS3540 delivers an expanded build volume beyond standard industrial SLS systems, enabling production of oversized mechanical components, full-scale functional prototypes, and end-use parts for automotive and aerospace applications. Utilizing advanced laser sintering technology, it maintains precision at scale while significantly reducing per-part costs compared to traditional large-format SLS solutions. Ideal for high-volume production of jigs, fixtures, and industrial tooling with superior mechanical properties and minimal material waste.

Fast Builds

Complete full-bed prints in 10 hours for rapid delivery of prototypes and production parts. Enables quick-turn manufacturing and efficient batch processing.

High-Capacity Loading

40kgs powder capacity enables extended uninterrupted production runs. Reduces refill frequency and maximizes throughput for large-scale industrial SLS manufacturing.

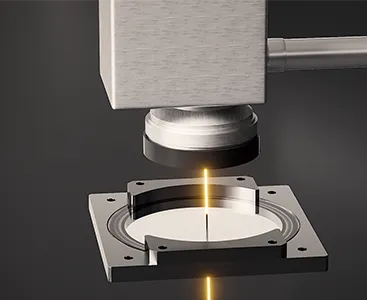

Dual-Laser Options

Configurable with Fiber or CO2 laser sources to match specific material requirements. Supports printing with both black and white polymer powders for enhanced application flexibility.

Broad Materials

Supports PA11, PA12, TPU with nitrogen assistance. Processes diverse materials for functional prototypes and end-use parts.

Spacious Workstation

Extra-large post-processing workstation provides ample space for handling big printed parts. Enables efficient cleaning and finishing of oversized SLS components with ease.

Drum Blasting

Rotary sandblasting system thoroughly cleans residual powder from model surfaces. Ensures pristine finish and reduces manual post-processing time for production parts.

Auto Powder Elevation

Automatically raises powder from build cylinder for effortless cleaning. Eliminates manual handling and reduces post-processing time for industrial SLS workflows.

Low Waste

10-20% packing density maximizes material usage with near-zero waste. Maintains high output while reducing powder consumption.

70% Recycled Ratio

Uses 30% new / 70% recycled powder mix, cutting material costs while ensuring high-quality results. Ideal for sustainable, cost-effective SLS production.

Sandblasting Ready

Integrated sandblasting preparation ensures smooth surface finishing. Saves time on post-processing and delivers professional-quality part appearance.

High-Volume Output

Delivers accelerated production speeds for large-batch manufacturing. Optimized for factory environments demanding rapid output of functional end-use components.

Oversized Build Capacity

Massive construction volume supports fabrication of large-scale mechanical parts. Tailored for automotive, aerospace, and heavy equipment manufacturing applications.