Standard 3D Printing Resin for SLA Printers | 355nm Wavelength | Supermaker

Engineered for precision, Supermaker Standard Resin enables high-accuracy 3D printing for professional use. It is ideal for functional testing, master patterns, and architectural models, offering dimensional stability and a superior surface finish ready for painting and post-processing. Achieve repeatable results for demanding applications.

Desktop Size

The machine size is only 57*48*80cm. Its space-saving design fits easily on any desk, perfect for home studios or workshops with limited space.

Top-Up Printing

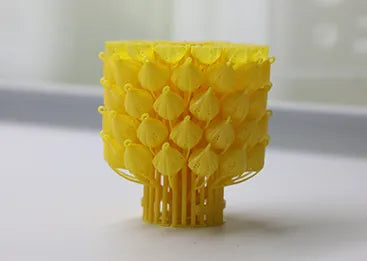

Unlike LCD printers that peel models downward, our innovative top-up printing method gently lifts finished pieces upward. This drastically reduces support material needs, minimizes model damage risks, and saves significantly on material waste.

Fast Printing

Uses high-speed DLP technology with 4K,405nm light source to cure layers in just 5-6 seconds. This rapid printing process is perfect for quick prototyping and efficient model production.

High Precision

Boasts an incredible 50μm XY resolution for exceptionally detailed models. This accuracy ensures smooth surfaces and precise details on every print.

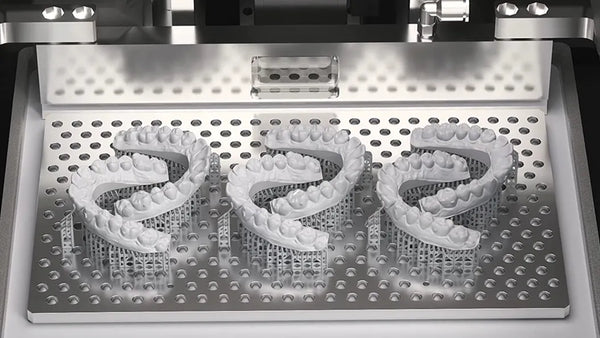

One Print Multiple Parts

Boost productivity with efficient small-batch printing capabilities. Perfectly suited for jewelry series or dental aligners, it reliably produces multiple high-precision models in a single print run, maximizing efficiency.

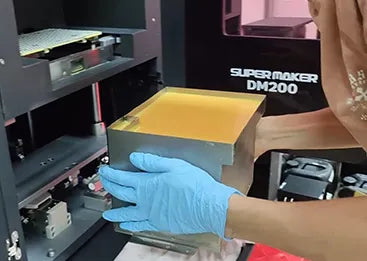

Easy-Swap Vat

6.5L large-capacity resin vat enables prolonged printing with minimal refills. Quick-release design allows effortless vat changes and maintenance, drastically reducing downtime and improving workflow efficiency for batch production.